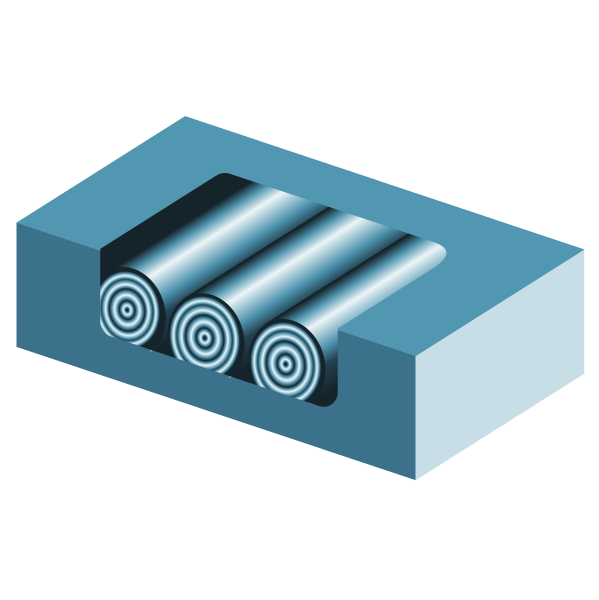

Resin: The basic raw material used in can liner manufacturing. The two basic types most commonly used are High Density and Linear Low Density

Gauge: The measure of a can liner's thickness. Usually expressed in mills or microns

Mil: A Thousandth of an inch. Linear Low Density can liners range from .30 to 6.0 mils. Convert a mil to a micron by multipling by 25.4

Micron: One millionth of a meter. High Density can liners can rage from 6-24 microns. Convert a micron to a mil by dividing by 25.4

Post-consumer: Material defined as waste material generated by households or by commercial, industrial and institutional facilities in their role as end-users of the product, which can no longer be used for its intended purpose.

Post-industrial: Material defined as waste material that has been generate from a manufacturing process, and has not been introduced tinto the consumer market.

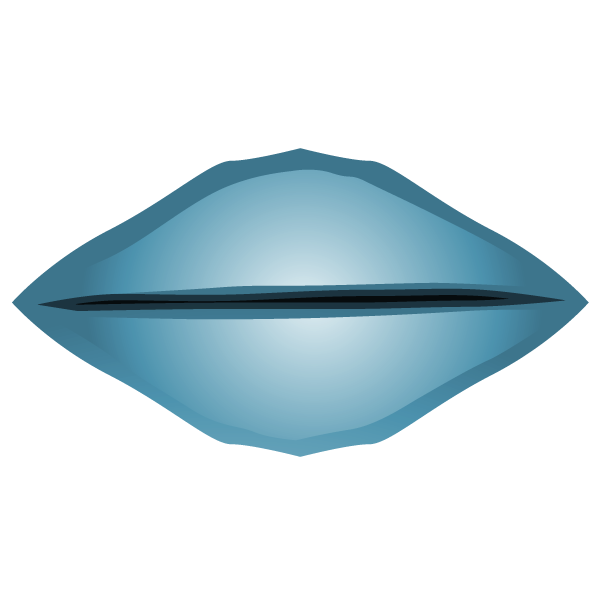

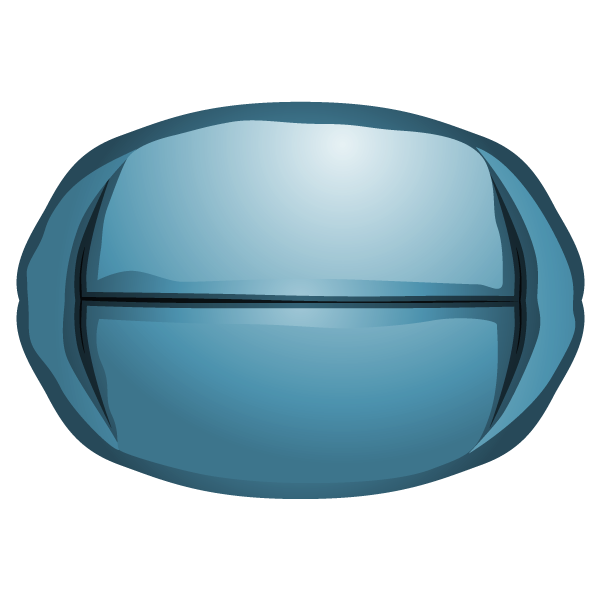

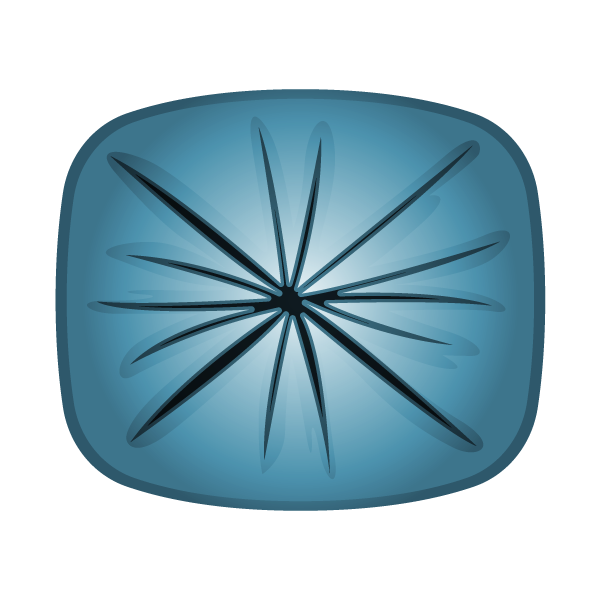

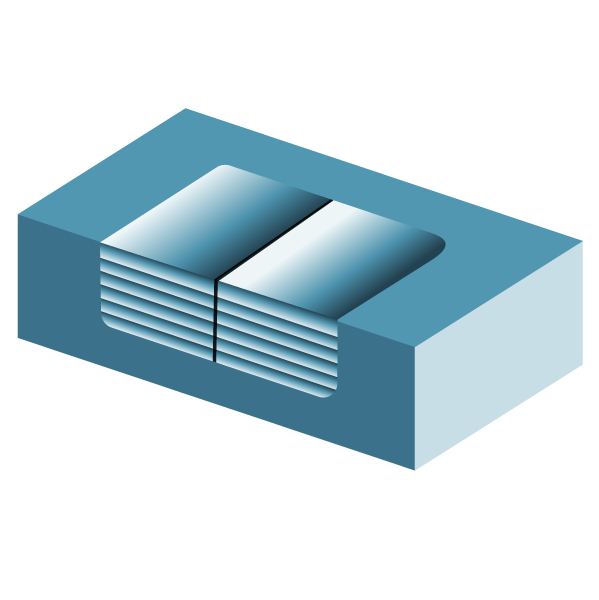

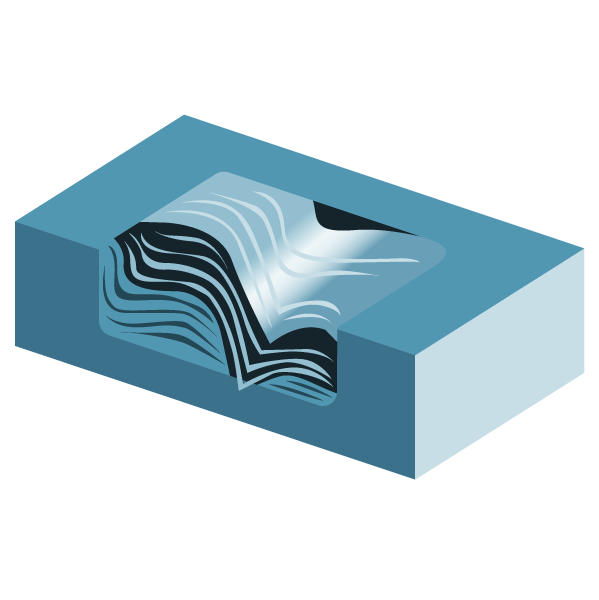

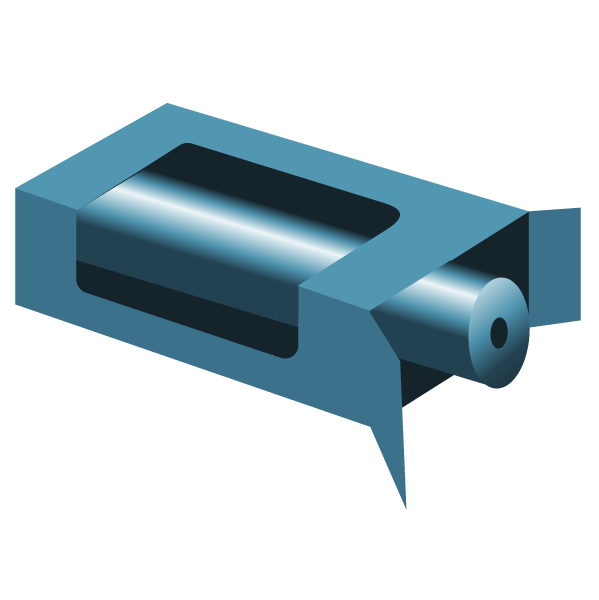

Following are the three most prevalent types of can liners bottom seals:

One of the most common mistakes in selling can liners, is selling a liner that does not properly fit the receptacle. A liner that falls inside the receptacle is too small, while a liner that has to be knotted at the top of the receptacle is too big. Selling a liner that is too big or too small for the container, opens the door for a competitor to take your business with a properly fitted product. A properly fitted liner has between three to five inches hanging over the top of the container

Often, receptacles have the gallon capacity printed or moleded on them. If you cannot find the gallon capacity on the receptavle, you can use the folllowing formula to determine the correct size can liner.

Width: To calculate the proper width of the ca liner for ytour container, divide the circumference of the container by 2.

Square Circumference: Sum of all 4 sides.

Round circumference: Diameter multiplied by 3.14.

Length: For round or square containers, add 4-5 inches (for overhang) to the height of the container.

Size Calculator

Resin is the basic raw material used in the manufacturing of plastic bags. The two most commonly used resins in manufacturing plastic can liners are Linear Low Density and High Density.

Can liners are available in many different gauges (film thickness), which determine the can liner’s strength. Generally, the thicker the gauge, the more weight the can liner can hold.

The cost of a can liner increases as the bags’ gauge gets thicker, therefore, the goal is to sell the thinnest bag possible that can perform for the application without failing. To simplify this process, NAPCO publishes the maximum dry load (weight) capacity of each bag. This allows you to simply determine the average weight of the waste going into the liner, and then find the closest max dry load corresponding to that weight.

Can liner color is often a matter of personal preference, although, as indicated below, it can also serve a purpose.

Black, Gray, Silver, Yellow (Applications where trash needs to be concealed)

White (Helps to convey a sanitary appearance and atmosphere)

Clear, Natural (Applications where trash needs to be monitored, such as theft prevention, sorting recycled material, and linen collection)